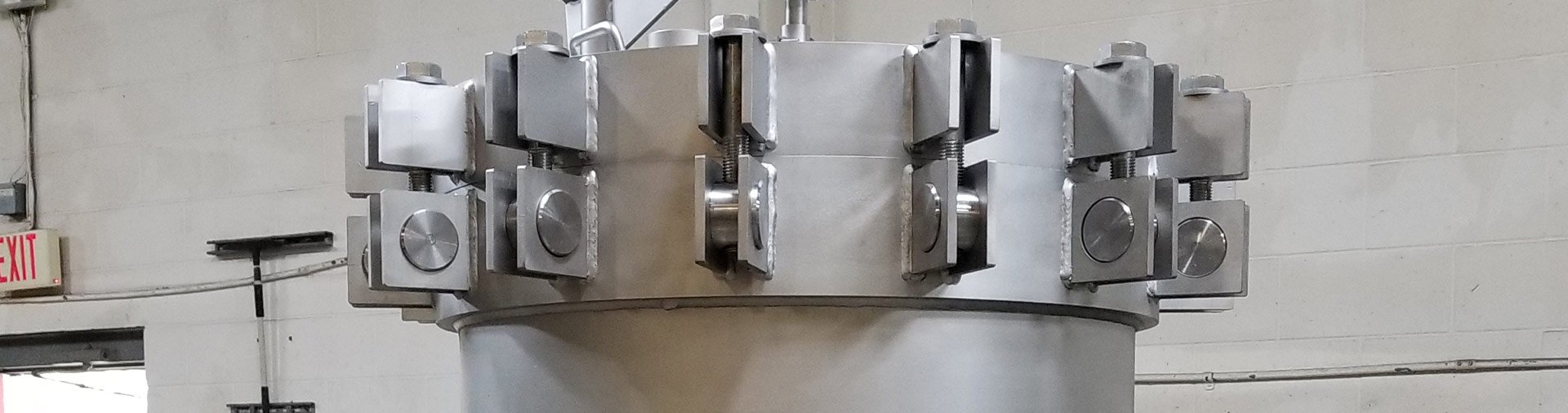

We Provide Professional Passivation

Passivation of stainless steel is the non-electric process of removing free iron from the surface of a part using a chemical solution as described in ASTM A967-01, AMS 2700, and QQ-P-35. Passivation is used to prevent the corrosion of stainless steel; this chemical process adds an oxide layer that protects it against outside reactions to air.